I've just fitted a

Nest Learning Thermostat to my central heating boiler.

I discovered a few weeks ago that the thermostat on my wall is not actually connected to the boiler. This would explain why I was unable to regulate my house temperature by adjusting it, the boiler is controlling itself.No wonder my house is hot.

We have thermostat valves on all the radiators bar one, and I thought we could do better.

I got a good deal on the Nest thermostat. Nest Labs were bought by Google in 2014 for $3.2 billion, and so I'm expecting great support from this product. It is WiFi enabled and iOS and Android apps allow you to control it remotely. It also has self learning modes, and given a zip/postal code, knows the external weather conditions, so it can learn how quickly your house heats to ensure you have the desired room temperature at a given time.

A web interface also allows for easy scheduling.

It comes with everything you need for a simple installation. The thermostat itself has a colour LCD display surrounded by a stainless steel rotary dial which is used to change settings. Pressing the dial like a mouse button confirms a selection.

It is manufactured exceedingly well and oozes quality.

The thermostat is connected to the boiler controller wirelessly. The boiler controller is mains powered and provides a SPDT relay for control of the heating system. In normal operation the now defunct boiler timer is set to always on.

The boiler controller also outputs a 12V d.c. supply to power the thermostat. Normally one would simply disconnect the old thermostat, and use the old cabling to supply the Nest. I was unable to do this in my installation, but the Nest controller comes with a USB style wall wart which is fine.

The thermostat mounts into a cradle, which can be attached to the included wall plate, or an optional stand. Interestingly, the wall plate has an inbuilt spirit level. I've never seen a product with that level of detail before.

Unable to utilise the position of the old thermostat, I wanted to try a few different positions in the house in order to find the best location.

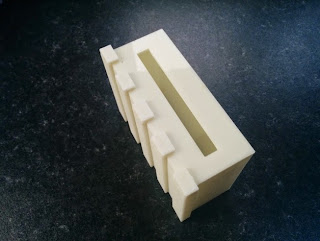

Nest supply an optional stand, but it costs around 30GBP. When I find the ideal spot, I want to wall mount the unit, but I'm not willing to splash out so I designed and 3D printed my own.

It's very much based on the official stand which has inbuilt power connections, whereas mine simply allows the supplied USB power cable to fit in the back of the unit.

I also added a flange at the back of the stand to prevent it falling over when operating the thermostat dial:

It's sitting in my dining room right now and seems to be doing what it is supposed to. The house certainly seems a bit cooler...which means I am spending less cash.

I've published the stand files on

Thingiverse.

%2B(Copy).jpg)

.jpg)